Rubber Rollers Manufacturer

Rubber Rollers Manufacturer

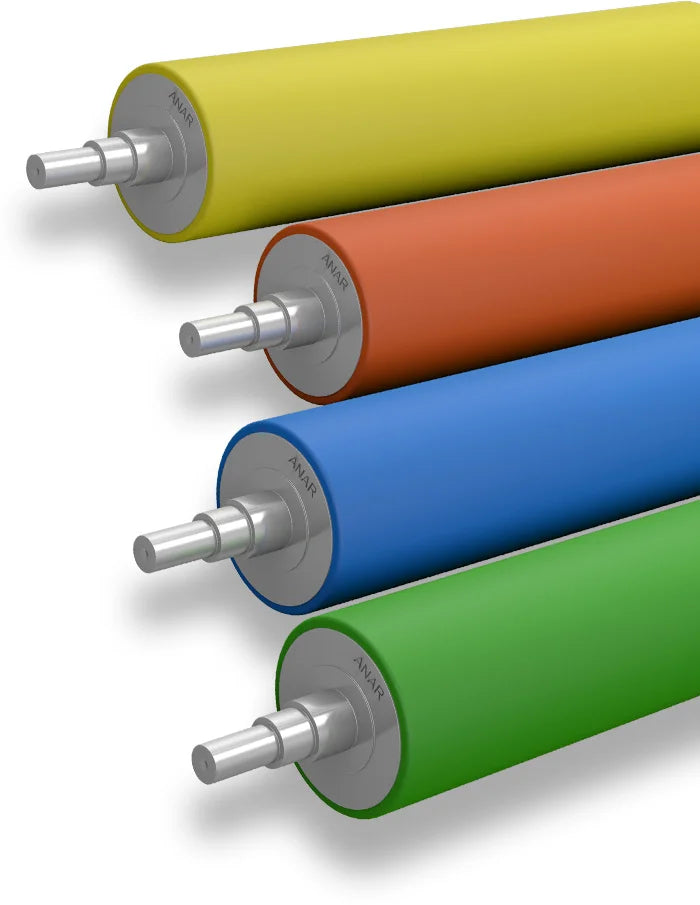

The Trusted Rubber Roller in India is manufactured mainly using high hydraulic pressure, which ensures a compact microstructure and longer service life and strength. The rubber roller we produce is designed to withstand even the toughest demands, such as temperature fluctuations or abrasives and solvents. We create customized solutions for various precise applications across different manufacturers. Our products are made with the latest technologies and innovative ideas. The industries we serve include printing, paper, plastic, packaging, and many others. Our mission is to provide our customers with the quality equipment they need to achieve the desired outcome as per their quality standards.

Our rubber rollers are specially designed to meet the finest requirements of applications in paper, textiles, plastic, and many other industries. It has proven its reliability time and time again in demanding environments. Rubber rolls manufactured at Hitechrolls Pvt. Ltd. provide a wide range of advantages, such as wear resistance, antistatic property, chemical resistance, heat resistance, non-stick surface, and friction resistance to our customers.

Share

Collapsible content

TYPES OF RUBBER ROLLERS

•Printing/Impression Furnishing Rollers.(Rotogravure, Flexographic Printing)

•Lamination Rollers (Solvent less/Solvent Base lamination)

•Film Plant Rollers (Nip Rollers, Drum Rollers, Transport Rollers)

•Diamond Groove Rollers & Customized Groove Rollers.

•Drive Rollers

•Guide Rollers

•Grooved Rollers

PRODUCTION PROCESS

•Core Roller Manufacturing

•Rubber Coating

•Rubber Grinding & Finishing

•Inspection

Industrial Rubber Roller

Hitechrolls Pvt. Ltd. is a leading industrial rubber roller manufacturer in Ahmedabad. Industrial rubber rolls are widely used for production in various fields. It is used in various industrial applications such as paper milling, textiles, printing, steel, packaging, plastic-processing, plywood, foam, etc. In addition, it is a highly finished, wear-resistant, and high-tensile industrial rubber roller that ensures an excellent finish.

Printing Rubber Roller

Hitechrolls Pvt. Ltd. is a leading industrial rubber roller manufacturer in Ahmedabad. Industrial rubber rolls are widely used for production in various fields. It is used in various industrial applications such as paper milling, textiles, printing, steel, packaging, plastic-processing, plywood, foam, etc. In addition, it is a highly finished, wear-resistant, and high-tensile industrial rubber roller that ensures an excellent finish.

Lamination Rubber Roller

Hitechrolls Pvt. Ltd. is a leading industrial rubber roller manufacturer in Ahmedabad. Industrial rubber rolls are widely used for production in various fields. It is used in various industrial applications such as paper milling, textiles, printing, steel, packaging, plastic-processing, plywood, foam, etc. In addition, it is a highly finished, wear-resistant, and high-tensile industrial rubber roller that ensures an excellent finish

SPECIFICATIONS- MATERIAL & DIMENTIONS

-

Shell Material

MS / SS / Aluminum

-

Diameter

Up To 800 Mm

-

Length

Up To 8000 Mm

-

Coating

Neoprene, Nitrile, Silicone, EPDM, Hypalon, SBR, Teflon, Polyurethane

Key Features of Our Rubber Rollers

-

Crowning is an optional process that shapes the roller to have varying diameters along its length. This creates a tapered, convex, or concave shape which allows a slight deflection when pressed against a load.

-

Groove cutting is the creation of specially designed depressed and elevated regions on the surface of the roller to increase the surface area of the roller, to prevent slippage, to improve heat dissipation, and to apply embossings and print patterns.

-

This process smoothens the surface of the rubber cover by removing protruding parts and leveling overlapping strips. Grinding is done by rolling the rubber roller against an abrasive wheel, typically in some kind of turning lathe.

-

High-Quality Rubber

-

Precision Machining

-

Dynamic Balancing

-

Chemical Resistance

-

Heat Resistance

Advantages of Rubber Roller

These rolls offer several advantages to their customers. Unlike metal rollers in transport systems, rubber rolls are characterized by the highest coefficient of friction, which enables good adhesion of moving components and parts. In addition, they can adapt to small changes resulting from the operation of machines. In addition, they have all the advantages of rubber. These rolls offer several advantages to their customers. Unlike metal rollers in transport systems, rubber rolls are characterized by the highest coefficient of friction, which enables good adhesion of moving components and parts. In addition, they can adapt to small changes resulting from the operation of machines. In addition, they have all the advantages of rubber.

The reason why rubber is a very popular material for creating rollers and moving things is that it can be repeatedly compressed and released without losing its original shape. A material that cannot maintain its shape and needs constant replacement can be completely ineffective for manufacturing processes. More so, rubber can absorb shocks, scratches, and injuries too making it one of the finest materials for industrial requirements. It is also relatively cheap to acquire and handle, offering a competitive price advantage. Another very big advantage of these rollers is that they can be recycled and used again and again, which supports the current scenario, which requires support for the ecosystem.