Nip rubber roll for tape manufacturing processes

Nip rubber roll for tape manufacturing processes

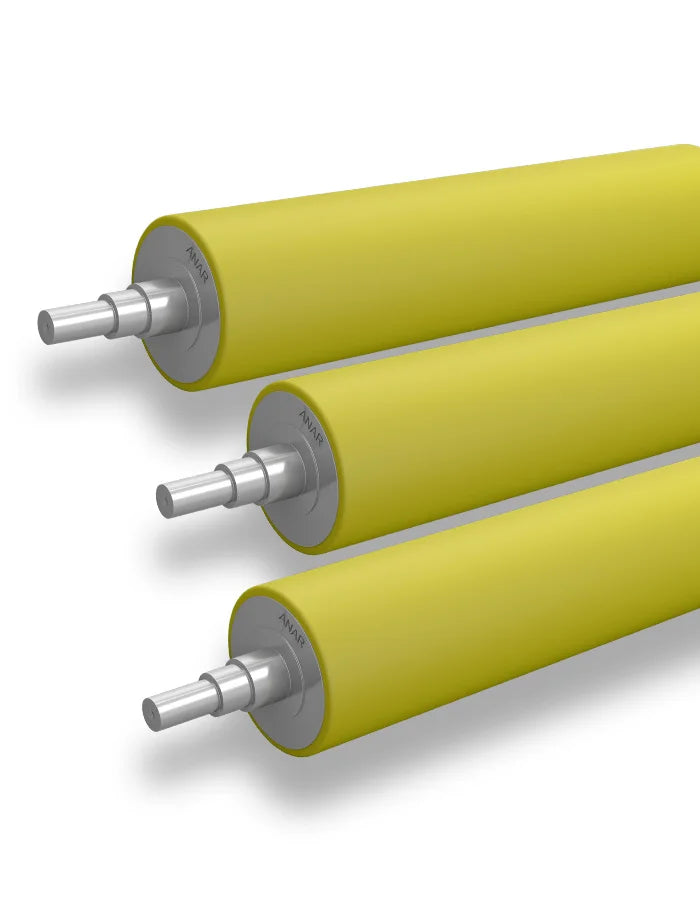

Welcome to the world of Nip Rubber Rolls, essential components in various industrial processes. Nip Rubber Rolls are used in applications where two rolls come into contact with each other to apply pressure or squeeze materials. These rolls play a crucial role in industries such as paper, printing, textile, and plastic processing, where precision and reliability are paramount.

Nip Rubber Rolls are designed to provide consistent pressure and traction, ensuring efficient and uniform processing of materials. They are made from high-quality rubber compounds that offer excellent wear resistance and durability, making them suitable for continuous operation in demanding environments. Whether you are looking for rolls for laminating, embossing, or squeezing applications, Nip Rubber Rolls are the go-to choice for industries worldwide.

The Nip Rubber Roller is engineered for precision and uniform pressure distribution in various industrial applications. Its unique design enhances material handling, ensuring smooth and consistent performance across processes. Built with high-quality materials, this roller is essential for maintaining efficiency and reducing wear in machinery. To explore more about our advanced solutions, visit our Rubber Roller page, where you'll find an array of products designed to meet your specific needs.

Share

Collapsible content

Types Of Rubber Roller

•Printing/Impression Furnishing Rollers.(Rotogravure, Flexographic Printing)

•Lamination Rollers (Solvent less/Solvent Base lamination)

•Film Plant Rollers (Nip Rollers, Drum Rollers, Transport Rollers)

•Diamond Groove Rollers & Customized Groove Rollers.

•Drive Rollers

•Guide Rollers

•Grooved Rollers

•Conveyor Rollers

•Dead Shaft Rollers

Production Process

•Core Roller Manufacturing

•Rubber Coating.

•Rubber Grinding & Finishing

•Inspection

High-Quality Rubber Compound

Our Nip Rubber Rolls are manufactured using a high-quality rubber compound that is specially formulated for durability and performance in industrial applications. This rubber compound offers exceptional wear resistance, ensuring that our rolls can withstand the rigors of continuous operation in various industrial processes. Additionally, the high-quality rubber compound used in our Nip Rubber Rolls provides excellent traction and pressure distribution, resulting in uniform material processing and high-quality finished products. The compound's resilience to harsh chemicals and temperatures makes our rolls suitable for diverse industrial environments.

Precision Engineering for Consistent Performance

Each Nip Rubber Roll is precision-engineered to provide consistent pressure and traction across its surface. This precision engineering ensures that our rolls deliver uniform material processing, resulting in high-quality finished products with precise dimensions and properties. Additionally, the precision engineering of our Nip Rubber Rolls guarantees reliable performance and maximizes the efficiency of industrial processes, reducing downtime and maintenance costs. Our rolls are designed to meet the specific requirements of various industrial applications, ensuring optimal performance and longevity.

Specifications detail material, dimensions,

-

Shell Material

MS / SS / Aluminum

-

Diameter

Up To 800 Mm

-

Length

Up To 8000 Mm

-

Coating

Neoprene, Nitrile, Silicone, EPDM, Hypalon, SBR, Teflon, Polyurethane

Key Features of Nip Rubber Rolls

-

Our Nip Rubber Rolls are made from a high-quality rubber compound that offers exceptional wear resistance and durability, ensuring long-lasting performance in industrial applications.

-

Each Nip Rubber Roll is engineered with a precision surface finish, ensuring uniform pressure distribution and consistent material processing.

-

Our Nip Rubber Rolls are designed to withstand high temperatures, making them suitable for use in a wide range of industrial processes.

-

High-Quality Rubber Compounds

-

Precision Surface Finish

-

Temperature Resistance

-

Corrosion Resistance

-

Customization Options

Advantages of Nip Rubber Rolls

Quality Assurance: We are committed to delivering high-quality Nip Rubber Rolls that meet the stringent demands of industrial applications. Our rolls undergo rigorous quality control checks to ensure they meet industry standards for performance and durability.

Customization Options: We understand that every industrial process is unique. That's why we offer customization options for our Nip Rubber Rolls, allowing you to tailor them to your specific requirements. Whether you need a specific size, hardness level, or surface finish, we can accommodate your needs.

Customer Satisfaction: At Anar Rub Tech Pvt. Ltd., customer satisfaction is our top priority. We strive to exceed your expectations, providing exceptional products and services that meet your needs and exceed your expectations.

Choose Anar Rub Tech Pvt. Ltd. for your Nip Rubber Roll needs and experience the difference in quality, performance, and service.