High-Quality Rotogravure printing roller vital component in the printing industry

High-Quality Rotogravure printing roller vital component in the printing industry

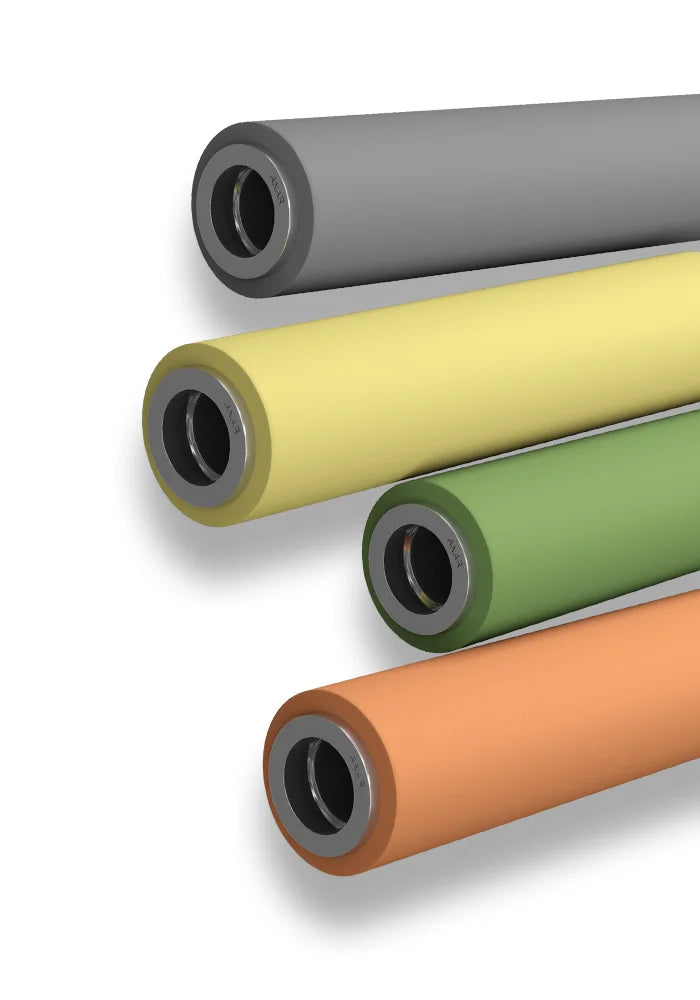

Welcome to the world of Rotogravure Printing Rollers, a vital component in the printing industry. These rollers play a crucial role in the rotogravure printing process, which is known for its high-quality, high-speed, and cost-effective printing capabilities. Rotogravure printing rollers are used to transfer ink to the printing substrate, such as paper, film, or foil, with exceptional precision and consistency. These rollers are typically made from materials like steel or copper and are engraved with microscopic cells that hold the ink.

The engraving process is critical, as it determines the quality and resolution of the printed image. Rotogravure printing roller manufacturer specialize in creating rollers known for their ability to produce sharp, detailed images with vibrant colors, making them ideal for printing high-quality packaging, labels, and decorative materials. As key players in the printing process, these manufacturers prioritize the quality and performance of Rotogravure Printing Rollers. They strive to engineer rollers that are durable, reliable, and capable of delivering consistent results over long print runs.

The Rotogravure Printing Roller stands out with its innovative design, tailored for exceptional print precision and consistency. Featuring advanced engineering, this roller guarantees vibrant, detailed prints by optimizing ink transfer. Its durable build ensures long-lasting performance, making it a vital component for high-quality printing. Dive deeper into our versatile range of solutions by exploring our Rubber Roller page, where cutting-edge technology meets industry excellence.

Share

Collapsible content

Types Of Rubber Roller

•Printing/Impression Furnishing Rollers.(Rotogravure, Flexographic Printing)

•Lamination Rollers (Solvent less/Solvent Base lamination)

•Film Plant Rollers (Nip Rollers, Drum Rollers, Transport Rollers)

•Diamond Groove Rollers & Customized Groove Rollers.

•Drive Rollers

•Guide Rollers

•Grooved Rollers

•Conveyor Rollers

•Dead Shaft Rollers

Production Process

•Core Roller Manufacturing

•Rubber Coating

•Rubber Grinding & Finishing

•Inspection

01. Roller Construction and Materials

Our Rotogravure Printing Rollers are constructed using high-quality materials such as steel or copper, known for their durability and stability. These materials are chosen for their ability to withstand the pressures and speeds of the printing process, ensuring consistent and reliable performance. The rollers are carefully crafted to precise specifications, with a focus on achieving the optimal balance between hardness and flexibility. This construction allows for uniform ink transfer and excellent print quality, making our rollers ideal for a wide range of printing applications. Our rollers undergo a thorough manufacturing process, starting from material selection to final inspection. We ensure that each roller is meticulously crafted to meet our high-quality standards.

02. Temperature Control and Thermal Stability

Our Rotogravure Printing Rollers are constructed using high-quality materials such as steel or copper, known for their durability and stability. These materials are chosen for their ability to withstand the pressures and speeds of the printing process, ensuring consistent and reliable performance. The rollers are carefully crafted to precise specifications, with a focus on achieving the optimal balance between hardness and flexibility. This construction allows for uniform ink transfer and excellent print quality, making our rollers ideal for a wide range of printing applications. Our rollers undergo a thorough manufacturing process, starting from material selection to final inspection. We ensure that each roller is meticulously crafted to meet our high-quality standards.

Specifications detail material, dimensions,

-

Shell Material

MS / SS / Aluminum

-

Diameter

Up To 800 Mm

-

Length

Up To 8000 Mm

-

Coating

Neoprene, Nitrile, Silicone, EPDM, Hypalon, SBR, Teflon, Polyurethane

Key Features of Rotogravure printing roller

-

Our Rotogravure Printing Rollers feature precision engraving, ensuring sharp and detailed prints with excellent image clarity.

-

Made from premium materials, our rollers are highly durable, providing long-lasting performance even under high-speed printing conditions.

-

Achieve consistent ink transfer with our rollers, leading to uniform print quality across all your printed materials.

-

Precision Engraving

-

High Durability

-

Consistent Ink Transfer

-

Chemical Resistance

-

Customizable Designs

Advantages of Rotogravure Printing Roller

Quality Assurance: We are committed to delivering the highest quality products to our customers. Our Rotogravure Printing Rollers undergo rigorous quality control checks to ensure that they meet the highest standards of performance and durability.

Customization Options: We understand that every printing application is unique. That's why we offer a wide range of customization options for our Rotogravure Printing Rollers, including engraving designs, roller diameters, and materials. This allows you to tailor our rollers to your specific printing needs.

Customer Satisfaction: At Hitechrolls Pvt. Ltd., customer satisfaction is our top priority. We work closely with our customers to understand their needs and provide them with the best possible solutions. Our commitment to customer satisfaction has earned us a reputation as a trusted and reliable supplier of Rotogravure Printing Rollers.

Choose Hitechrolls Pvt. Ltd. for your Rotogravure Printing Roller needs and experience the difference in quality, performance, and service.