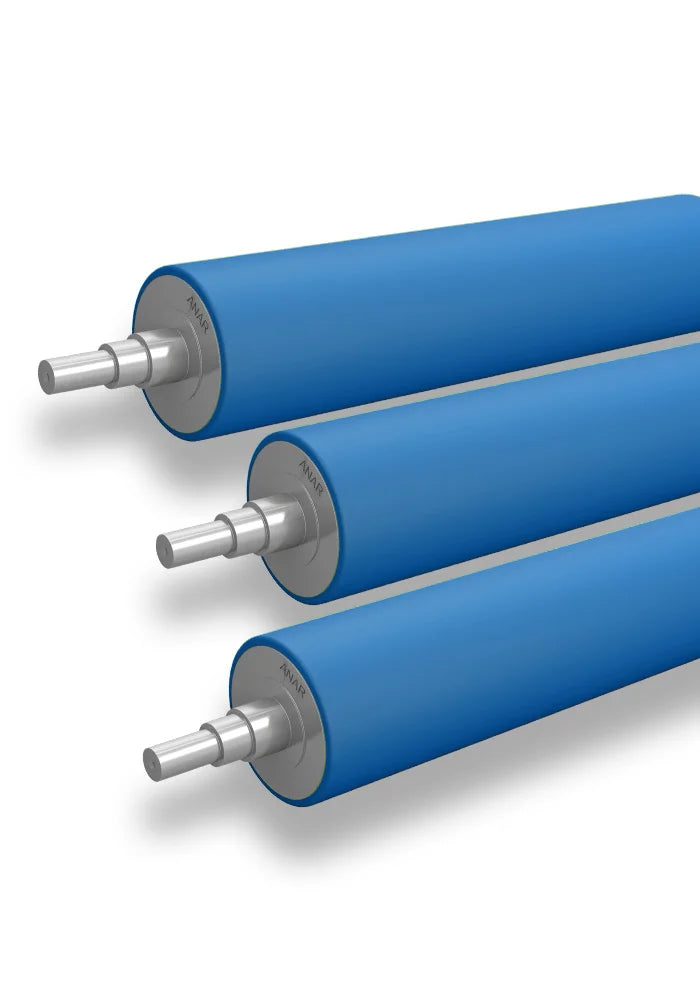

High-Quality Lamination rubber roller superior grip on materials

High-Quality Lamination rubber roller superior grip on materials

Hitechrolls Pvt. Ltd. offers a premium range of lamination rubber rollers designed to meet the stringent demands of the lamination industry. These rollers are crafted with high-quality rubber compounds, ensuring exceptional durability and wear resistance. This quality construction guarantees long-lasting performance, making them ideal for continuous use in various lamination applications.

Our lamination rubber rollers are precision engineered to deliver consistent and uniform pressure distribution across the entire surface. This precision ensures flawless lamination results, minimizing the risk of defects such as wrinkles and bubbles. The rollers are customizable to meet specific requirements, including size, hardness, and surface finish. This customization capability allows us to tailor the rollers to your exact specifications, ensuring optimal performance in your lamination process. As a leading lamination rubber roller manufacturer, we prioritize quality and reliability in every roller we produce.

With superior performance and reliability, our lamination rubber rollers provide consistent and uniform pressure, ensuring optimal lamination quality. They are designed to withstand continuous use in demanding lamination applications, making them a reliable choice for professionals in the industry. Our experienced team of professionals is also available to provide expert technical support, guiding you in selecting the right roller for your specific needs. Choose Hitechrolls Pvt. Ltd. for precision-engineered lamination rubber rollers that deliver perfect results every time.

Share

Collapsible content

Types Of Rubber Roller

•Printing/Impression Furnishing Rollers.(Rotogravure, Flexographic Printing)

•Lamination Rollers (Solvent less/Solvent Base lamination)

•Film Plant Rollers (Nip Rollers, Drum Rollers, Transport Rollers)

•Diamond Groove Rollers & Customized Groove Rollers.

•Drive Rollers

•Guide Rollers

•Grooved Rollers

•Conveyor Rollers

•Dead Shaft Rollers

Production Process

•Core Roller Manufacturing

•Rubber Coating

•Rubber Grinding & Finishing

•Inspection

01. Durable and Versatile Lamination Rubber Rollers

Our lamination rubber rollers are designed to withstand the rigors of continuous use, making them ideal for a wide range of lamination applications. They are crafted from high-quality rubber compounds, ensuring exceptional durability and wear resistance. These rollers are also customizable, allowing for precise tailoring to meet specific requirements such as size, hardness, and surface finish. With their superior performance and reliability, our lamination rubber rollers provide consistent and uniform pressure distribution for flawless lamination results.

Precision Engineered for Optimal Performance

Our lamination rubber rollers are designed to withstand the rigors of continuous use, making them ideal for a wide range of lamination applications. They are crafted from high-quality rubber compounds, ensuring exceptional durability and wear resistance. These rollers are also customizable, allowing for precise tailoring to meet specific requirements such as size, hardness, and surface finish. With their superior performance and reliability, our lamination rubber rollers provide consistent and uniform pressure distribution for flawless lamination results.

Specifications detail material, dimensions,

-

Shell Material

MS / SS / Aluminum

-

Diameter

Up To 800 Mm

-

Length

Up To 8000 Mm

-

Coating

Neoprene, Nitrile, Silicone, EPDM, Hypalon, SBR, Teflon, Polyurethane

Key Features of Lamination rubber roller

-

Exceptional durability and wear resistance. Our lamination rubber rollers are made from high-quality rubber compounds, ensuring exceptional durability and wear resistance for long-lasting performance

-

Ensures consistent pressure distribution. Precision engineering guarantees consistent and uniform pressure, minimizing the risk of defects for flawless lamination results.

-

Tailored to specific requirements. We offer customization options for size, hardness, and surface finish to meet your exact needs.

-

High-Quality Rubber Compound

-

Precision Engineered

-

Customizable

-

Superior Performance

-

Reliable

Advantages of Lamination rubber roller

Hitechrolls Pvt. Ltd. stands out as a premier choice for lamination rubber rollers due to its exceptional quality, cutting-edge technology, and unwavering commitment to customer satisfaction. The company's lamination rubber rollers are engineered to deliver superior performance and durability, making them ideal for a wide range of industrial applications.

One of the key advantages of Hitechrolls's lamination rubber rollers is their precision engineering. Each roller is carefully crafted to meet exacting specifications, ensuring optimal performance and consistency. This level of precision is crucial in lamination applications, where even minor deviations can lead to defects in the finished product.

Another factor that sets Hitechrolls apart is its use of high-quality materials. The company's lamination rubber rollers are made from premium rubber compounds that are specially formulated for maximum durability and performance. This ensures that the rollers can withstand the rigors of continuous use in demanding industrial environments.

Additionally, Hitechrolls offers a wide range of customization options for its lamination rubber rollers. Customers can choose from various sizes, configurations, and surface finishes to meet their specific requirements. This flexibility allows customers to tailor the rollers to their exact needs, ensuring optimal performance and efficiency. In conclusion, Hitechrolls Pvt. Ltd. is the preferred choice for lamination rubber rollers due to its superior quality, advanced technology, and commitment to customer satisfaction.