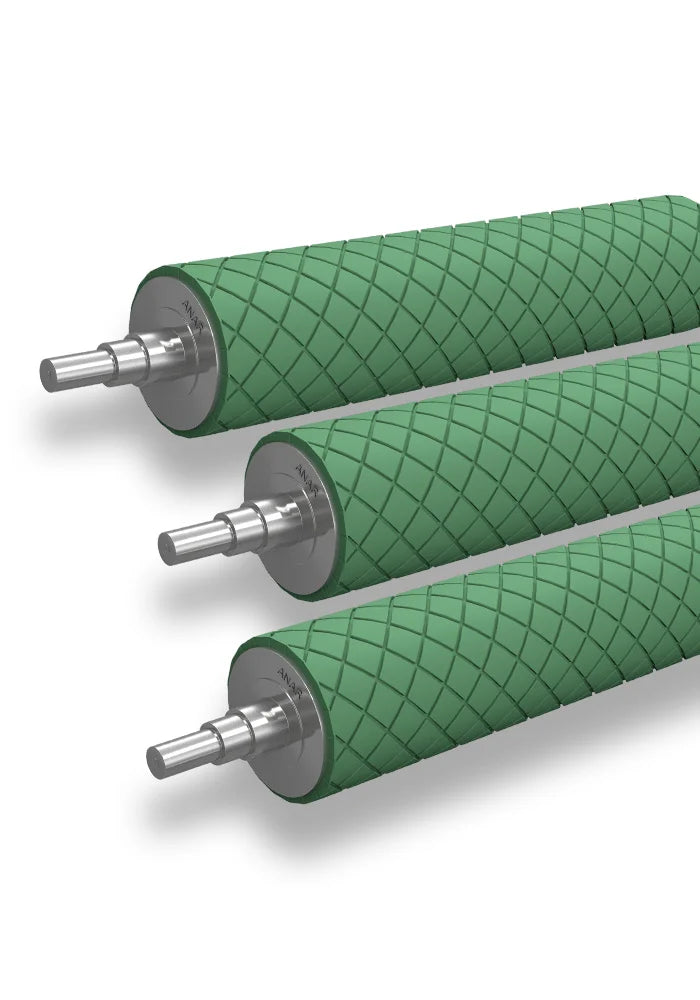

High-Quality Groove rubber roller for tape manufacturing processes

High-Quality Groove rubber roller for tape manufacturing processes

The Groove Rubber Roller is a specialized roller used in various industrial applications, known for its unique grooved surface. These grooves are designed to enhance the roller's performance and efficiency in specific tasks, such as material handling, printing, laminating, and more. The grooves on the roller's surface can vary in size, depth, and pattern, depending on the intended application.

The grooves on the rubber roller's surface, crafted by a leading groove rubber roller manufacturer, provide increased traction, allowing for better grip on materials being processed. This is particularly useful in applications where a firm grip is required to prevent slippage or misalignment. The grooves help in the release of trapped air between the roller and the material, ensuring smooth and uniform processing. This is especially beneficial in applications where air bubbles can negatively impact the final product's quality. The grooves also help distribute pressure more evenly across the roller's surface, reducing wear and tear and extending the roller's lifespan. This makes the groove rubber roller a cost-effective solution in the long run.

Groove rubber rollers can be customized to suit specific application requirements. This includes varying groove patterns, sizes, and depths, as well as different rubber compounds to suit the material being processed. The groove rubber roller is used in printing, packaging, textiles, and more for processes like embossing, laminating, coating, and conveying, thanks to its efficient grooved surface.

Share

Collapsible content

Types Of Rubber Roller

•Printing/Impression Furnishing Rollers.(Rotogravure, Flexographic Printing)

•Lamination Rollers (Solvent less/Solvent Base lamination)

•Film Plant Rollers (Nip Rollers, Drum Rollers, Transport Rollers)

•Diamond Groove Rollers & Customized Groove Rollers.

•Drive Rollers

•Guide Rollers

•Grooved Rollers

•Conveyor Rollers

•Dead Shaft Rollers

Production Process

•Core Roller Manufacturing

•Rubber Coating

•Rubber Grinding & Finishing

•Inspection

Technical Specifications of Groove Rubber Roller

The Groove Rubber Roller is engineered with precision to meet the demanding requirements of industrial applications. The grooves on its surface are carefully designed to optimize traction and air release, enhancing the roller's performance. These grooves are customizable in terms of size, depth, and pattern, allowing for tailored solutions for specific applications. Additionally, the roller's core is made of high-quality materials like aluminum or steel, ensuring durability and longevity. Its surface can be coated with specialized materials to further enhance its grip and adhesion properties, making it ideal for a wide range of industrial processes.

Precision Engineering for Optimal Performance

The groove rubber roller is equipped with precision bearings that ensure smooth and consistent rotation, reducing vibrations and ensuring uniform pressure distribution. This precision engineering results in enhanced performance and efficiency in processes such as material handling, printing, laminating, and more. The roller's surface treatment further enhances its functionality, providing excellent grip and adhesion for various materials. Overall, the groove rubber roller is a reliable and versatile component that offers superior performance in a wide range of industrial applications.

Specifications detail material, dimensions

-

Shell Material

MS / SS / Aluminum -

Diameter

Up To 800 Mm

-

Length

Up To 8000 Mm

-

Coating

Neoprene, Nitrile, Silicone, EPDM, Hypalon, SBR, Teflon, Polyurethane

Key Features of Groove Rubber Roller

-

The Groove Rubber Roller features a precision-designed groove pattern that enhances traction and air release, ensuring optimal performance in various industrial applications.

-

Built with a sturdy core and high-quality rubber, this roller is designed to withstand heavy-duty use, providing long-lasting durability and reliability.

-

The roller offers customizable groove options, allowing for tailored solutions to meet specific application requirements and achieve optimal performance.

-

Precision Groove Design

-

Durable Construction

-

Customizable Groove Options

-

Enhanced Material Handling

-

Efficient Air Release

Advantages of Groove Rubber Roller

Quality Assurance: At Anar Rub Tech Pvt. Ltd., quality is our top priority. Our groove rubber rollers undergo rigorous quality control measures to ensure that they meet the highest standards of performance and durability.

Customization Options: We understand that every application is unique, which is why we offer customization options for our groove rubber rollers. Whether you need a specific groove pattern, size, or material, we can tailor our rollers to meet your exact requirements.

Excellent Customer Service: Customer satisfaction is at the core of our business. Our dedicated team of professionals is always ready to assist you with any queries or concerns you may have regarding our products or services.

Choose Anar Rub Tech Pvt. Ltd. for your groove rubber roller needs and experience the difference that quality, expertise, and customer service can make.